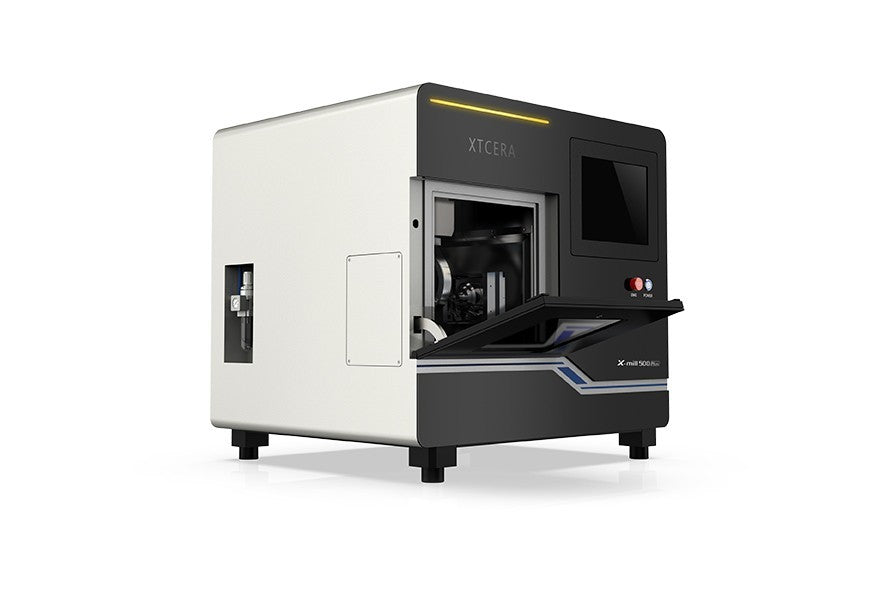

X-Mill 500 Plus Milling Machine

Advanced 5 axis Dry milling From £17500 In stock

DentalCAD 3.1 Rijeka cuts down on design time and offers

more intuitive workflows from CAD to CAM.

High-precision dental model prints NextDent Model 2.0 is characterized by its high degree of accuracy, making this material suitable for detailed ...

View full detailsHigh-quality material for 3D printing trays NextDent Tray is a biocompatible Class I material designed to print individual impression trays. The m...

View full detailsFlexibility in printing model parts NextDent Gingiva Mask is a flexible material that can be used in combination with the model material. This mak...

View full detailsNextDent SG (Surgical Guide) Design and print high-precision transparent drilling template NextDent SG is a biocompatible Class I material,...

View full detailsBalancing opacity and translucency perfectly NextDent C&B Micro Filled Hybrid is a biocompatible Class IIa material* developed for crowns and ...

View full detailsFlexible material for orthodontic applications NextDent Indirect Bonding Tray is a biocompatible Class I material for orthodontic applications. Ma...

View full detailsAesthetically pleasing 3D print material NextDent Ortho Clear is a is a biocompatible Class IIa material for all types of splints and retainers. I...

View full detailsTransparent 3D print material for Splints and Retainers NextDent Ortho Flex is a clear biocompatible Class IIa material developed for 3D printed D...

View full details

Grinding tool glass-ceramics Diameter: 2.5 mmShaft: 3 mm

Radius milling tool Diameter: 1 mmShaft: 3 mm

T22 - 1.0 I 3.0 MM RADIUS GRINDING TOOL (DIAMOND) GLASS CERAMICS Grinding tool glass-ceramics Diameter: 1 mmShaft: 3 mm

Use this section to help find the products you are looking for.

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}