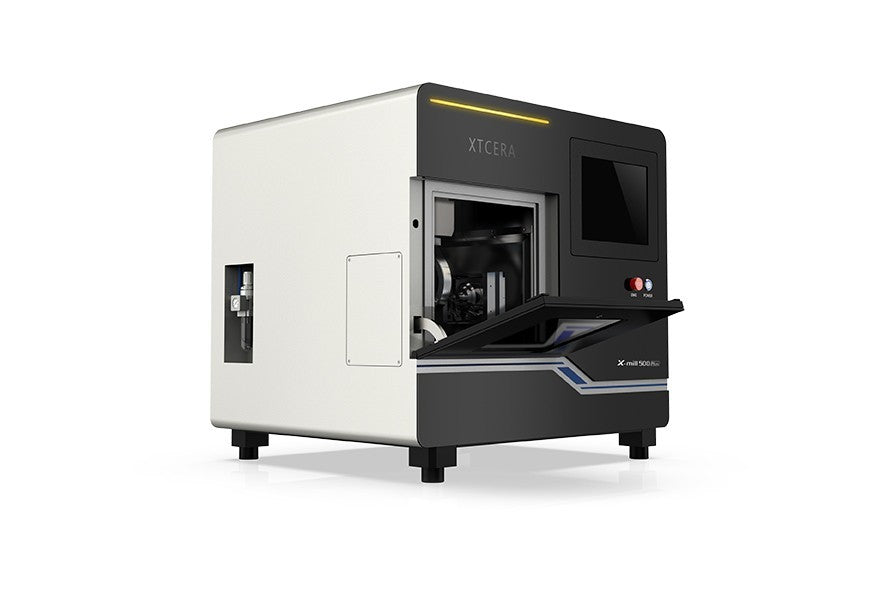

X-Mill 500 Plus Milling Machine

Advanced 5 axis Dry milling From £17500 In stock

DentalCAD 3.1 Rijeka cuts down on design time and offers

more intuitive workflows from CAD to CAM.

loT application, High performance 5-Axis and 3+2 linkage mode for accurate cutting Up to 90° large angle for buccal side cutting Built-in PC with ...

View full detailsScan without blind angle More comprehensive scanning, more realistic texture Camera principle remains the same, faster, more accurate, more ...

View full detailsUPCERA A7+ Double-layer metal protection around the chamber and Temperature compensation Vacuum Technology Built-inof error warning II...

View full detailsEXPLORE FUNCTIONAL- New Generation Multilayer Zirconia Upcera's explore Functional is comprised of 5 layers of dental multilayer zirconium ox...

View full details

Grinding tool glass-ceramics Diameter: 2.5 mmShaft: 3 mm

Radius milling tool Diameter: 1 mmShaft: 3 mm

T22 - 1.0 I 3.0 MM RADIUS GRINDING TOOL (DIAMOND) GLASS CERAMICS Grinding tool glass-ceramics Diameter: 1 mmShaft: 3 mm

Use this section to help find the products you are looking for.

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}